Speed controllers explained.

Why Use Speed Controllers & Limiters ?

In today’s ever growing markets there is a continual need to be able to control a motor's speed for various applications.

Sometimes there is a need to limit, or to ramp up and down an electric device to meet certain applications and uses, and that is where speed control comes into play.

Speed limiters –

Speed limiters are ideally suited for a set and forget low cost situation.

These are used to set a certain speed or limit, usually for air balancing, commissioning purposes, reducing airflow, motor noise or when the required airflow or maximum required is not known until the installation is complete.

Speed Controllers –

Speed controllers are used in applications where user adjustable speed or limit control is required. This allows the user to control the speed of the device either varied up or down as required.

Speed controllers may have a pre-set minimum speed / limit adjustment set during manufacturing, such as Powerform's controllers. This allows a minimum speed or limit for your application so the unit will always perform as you need it to and will avoid the installation to be controlled to run too slowly, or below its designed parameters by an end user.

In fan applications this can be critical, as this can lead to the fan motor stalling (drawing power but not turning, therefore there is no airflow to assist the motor to cool). This can cause the fan motor to overheat and cause it fail prematurely, sometimes within months of installation.

VSD, Variable Speed Drive

Variable speed drives (VSDs) are a controller that regulates the speed and rotational force, or torque output of an electric motor.

VSDs are also called variable-frequency drives, adjustable-speed drives, variable-frequency inverters, or frequency converters. VSD installations can increase energy efficiency (in some cases energy savings can be more than 50%), as they can change the speed of an electric motor by controlling the power that is fed into the machine.

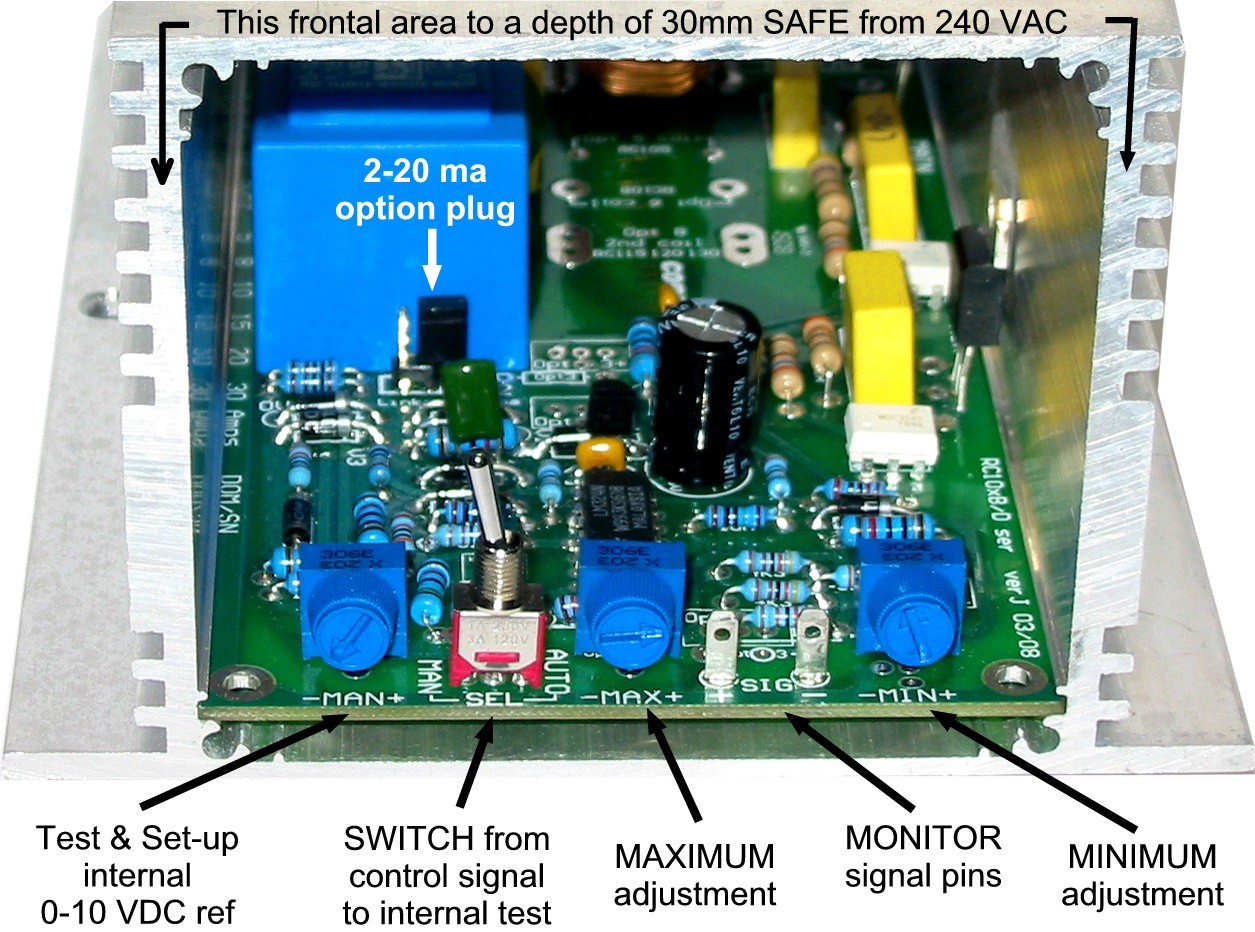

Powerform range of vsd’s feature dual control inputs as standard of 0 to 10 volt and 2 to 20 milliamps, and are easily switched from one input to the other by simply changing a jumper link internally. They also feature inbuilt EMI filters, auto off under 0.8v/1.5ma control signal, and minimum and maximum span & offset adjustment (min & max speed) ,ensuring they can meet every application and requirement.

Powerform controls offer a wide range of single phase speed controllers, limiters, vsd's and timers to suit every need. All Powerforms drives are suitable for PSC motors, fans, blowers and pumps, or applications where the torque varies with speed. They can also provide effective electronic control of other types of resistive and inductive loads eg – lamps, transformers & heaters. We are always more than happy to work with our clients to work out a solution for your speed controlling needs.

If you would like to know more about Powerform's range of controllers give us a call or get in contact with us.